Here you can download the free lecture Notes of Design of Machine Members 2 Pdf Notes – DMM 2 Notes with multiple file links to download. Design of Machine Members 2 Pdf Notes – DMM 2 Notes Pdf book starts with the topics covering Types of Journal bearings, Types of rolling contact bearings, Thrust in connecting I rod, Transmission of power by Belt and Rope drives, Load concentration factor, Square ACME, Helical and Bevel gears, Worm gears Properties of worm gears, Etc.

The Design of Machine Members 2 Pdf Notes – DMM 2 Notes Pdf file

DMM 2 pdf notes – DMM 2 notes pdf file to download are listed below please check it

Complete Notes

Link: Complete Notes

Note :- These notes are according to the R09 Syllabus book of JNTU. In R13 and R15,8-units of R09 syllabus are combined into 5-units in R13 and R15 syllabus. If you have any doubts please refer to the JNTU Syllabus Book.

UNIT -I

SLIDING CONTACT BEARINGS: Types of Journal bearings – basic modes of Lubrication — Bearing construction – bearing design – bearing materials — Selection of lubricants.

UNIT – II

ROLLING CONTACT BEARINGS: Types of rolling contact bearings — selection of bearing type – selection of bearing life – Design for cyclic loads and speeds – Static and dynamic loading of ball & roller bearings.

UNIT- III

DESIGN OF I C ENGINE PARTS: Connecting Rod : Thrust in connecting I rod – stress due to whipping action on connecting rod ends – Cranks and Crank shafts. strength and proportions of over hung and center cranks – Crank pins. Crank shafts. Pistons. Forces acting on piston – Construction Design and proportions of piston.. Cylinder. Cylinder liners.

UNIT-IV

POWER TRANSMISSIONS SYSTEMS, PULLEYS: Transmission of power by Belt and Rope drives . Transmission efficiencies, Belts – Flat and V types – Ropes – pulleys for belt and rope drives. Materials. Chain drives.

UNIT – V

SPUR GEAR DRIVES: Spur gears- Load concentration factor ~ Dynamic load factor. Surface compressive strength – Bending strength — Design analysis of spur gears – Estimation of centre distance, module and face width. check for plastic deformation. Check for dynamic and wear considerations.

UNIT-VI

HELICAL AND BEVEL GEAR DRIVES: Helical and Bevel gears – Load concentration factor – Dynamic load factor. Surface compressive strength – Bending strength — Design analysis of Helical and Bevel gears – Estimation of centre distance. module and face width, check for plastic deformation. Check for dynamic and wear considerations.

UNIT-VII

DESIGN OF POWER SCREWS: Design of screw. Square ACME . Buttress screws. design of nut. compound screw. differential screw. ball screw- possible failures.

UNIT-VIII

DESIGN OF WORM GEARS: Worm gears Properties of worm gears – Selection of materials —‘ Strength and wear rating of worm gears — Force analysis – Friction in worm gears- thermal considerations.

Reference

l. Machine Design by V. Bandari. TMH Publishers

2. Machine Design I R.N. Norton

3. Mach. Engg . Design I IE Shigley

4. Design of machine elements by Pandya and Shah

Text books

1. Design of Machine Elements by Kulkarni. Mc Graw Hill

2. Machine Design, by T.V.Sundararajan Murthy and Shanmugam – Anuradha Publications.

3. Design Data Books – P.S.G. College of Technology – Mahadevan

Frequently Asked Questions

Q1: What are the classifications of machine design?

A1: Machine design can be classified into,

- Developmental design

- Adaptive design

- New design – rational design, empirical design, industrial design, system design, computer aided design, optimum design, element design

Q2: What are the general consideration in Machine design?

A2: Some of the general considerations in Machine design are,

- Type of stresses and load caused by the load

- Machine’s motion of the kinematics or the parts

- Material selection

- Size and form of the parts

- Lubrication and fictional resistance

- Economical and convenient failures

- Standard parts usage

- Operation safety

- Facilities at workshop

- Number of machines to be manufactured

- Construction cost

- Assembling

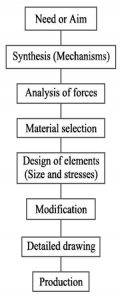

Q3: What is the procedure in Machine design?

A3: There is no fixed rule in designing a machine component. It may be designed in several ways. The general procedure that can be followed is as follows,

Q4: What are the classification of engineering materials?

A4: Classification of engineering materials are as below

- Metals, their alloys (Iron, steel, copper, aluminium etc)

- Non metals (Rubber, glass, plastic)

The metals are again classified into

- Ferrous metals which have iron as their main constitute

- No ferrous metals have metal any other than iron as their main constitute

Q5: What are the factors to be considered before selecting the materials for engineering purposes?

A5: Major factors like physical, mechanical and chemical properties of the materials make up the utility of the material. Need to be very careful in selecting the materials which is one of the most difficult problems for a designer. Factors to be considered before selecting the materials for engineering purposes are,

- Availability

- Suitability

- Cost