Theory of Metal Cutting PDF VSSUT – TMC PDF VSSUT of Total Complete Notes

Please find the download links of Theory of Metal Cutting PDF VSSUT | TMC PDF VSSUT are listed below:

Link: Complete Notes

Link: Module – 1

Link: Module – 2

Link: Module – 3

Link: Module – 4

Theory of Metal Cutting Notes VSSUT | TMC Notes VSSUT Free Lecture Notes Download 2025

If you’re pursuing a B. Tech degree and need a comprehensive resource for Theory of Metal Cutting (TMC), VSSUT provides detailed notes that cover essential concepts and practical applications in metal cutting. These notes are a vital part of your curriculum and will aid in understanding complex topics related to metal cutting processes.

Theory of Metal Cutting Notes Pdf

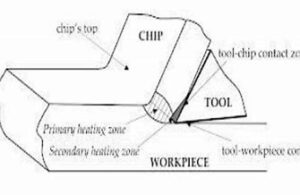

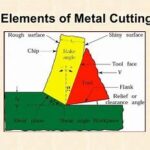

Theory of Metal Cutting (TMC) is a fundamental subject for mechanical and manufacturing engineering students. It focuses on the principles, processes, and techniques involved in cutting metals, a crucial aspect of manufacturing and production engineering. VSSUT’s notes on TMC provide a thorough understanding of these processes and their theoretical underpinnings.

Description of Theory of Metal Cutting Notes, PDF, Syllabus, Books | B Tech (2025)

The Theory of Metal Cutting (TMC) notes from VSSUT are designed to offer a detailed examination of metal cutting processes, stress analysis, and plasticity theory. These notes are particularly useful for students preparing for exams, working on projects, or seeking a deeper understanding of metal cutting.

Overview of TMC Notes Pdf

The notes are divided into four main modules, each covering different aspects of metal cutting. The content is structured to provide both theoretical knowledge and practical insights into metal cutting processes.

Module – 1: Fundamentals of Stress and Strain Analysis

- Review of Two-Dimensional Stress and Strain: This section provides an overview of stress and strain in two dimensions, essential for understanding more complex stress states.

- State of Stress in Three Dimensions: Examination of stress states in three dimensions, including stress tensors and invariants.

- Mohr’s Circle for 3-Dimensional State of Stress: Visualization and analysis of three-dimensional stress states using Mohr’s Circle.

- Strain at a Point – Mohr’s Circle for Strain: Analysis of strain at a point using Mohr’s Circle for strain.

- Hydrostatic & Deviatory Components of Stress: Understanding the components of stress and their implications in metal cutting.

- Elastic Stress-Strain Relations: Study of elastic stress-strain relationships, fundamental for analyzing material behavior under cutting forces.

Module – 2: Theory of Plasticity and Yield Criteria

- Elements of Theory of Plasticity: Introduction to plastic deformation, including flow curves, true stress, and true strain.

- Yield Criteria for Ductile Metals: Discussion of yield criteria such as Von Mises and Tresca, essential for predicting metal behavior during cutting.

- Combined Stress Tests: Analysis of metals under combined stress conditions.

- Yield Locus and Anisotropy in Yielding: Study of the yield locus and how material properties affect yielding.

- Yield Surface: Understanding the yield surface in plasticity theory.

- Levy-Mises and Prandtl-Reuss Stress-Strain Relations: Detailed look at stress-strain relations in plastic deformation.

- Hydrostatic & Deviatory Components of Stress: Further analysis of stress components and their role in metal cutting.

- Elastic Stress-Strain Relations: Review of elastic stress-strain relationships and their application in cutting processes.

- Classification of Forming Processes: Overview of different metal forming processes and their classification.

- Variables in Metal Forming and Their Optimization: Identification and optimization of variables affecting metal cutting processes.

Module – 3: Analysis of Deformation Processes

- Method Based on Homogeneous Compression: Examination of deformation processes using homogeneous compression methods.

- Slip Line Field Theory: Introduction to slip line field theory for analyzing deformation mechanisms.

- Upper Bounds and Lower Bounds: Methods for estimating upper and lower bounds in deformation processes.

- Slab Method of Analysis: Application of the slab method to analyze deformation.

- Flow Stress Determination: Techniques for determining flow stress in metal cutting.

- Hot Working and Cold Working: Differences between hot and cold working processes and their impact on cutting.

- Strain Rate Effect: Study of strain rate effects on metal cutting.

- Friction and Lubrication: Role of friction and lubrication in cutting processes.

- Deformation Zone Geometry: Understanding the geometry of the deformation zone in metal cutting.

- Workability and Residual Stress: Study of workability and residual stresses in cutting processes.

Module – 4: Process Analysis

- Forging: Load Calculation in Plane Strain Forging: Methods for calculating loads in plane strain forging.

- Rolling: Forces and Geometrical Relationships in Rolling: Analysis of forces and geometric relationships in rolling.

- Rolling Load and Torque in Cold Rolling: Calculation of load and torque in cold rolling processes.

- Von-Karman Work Equation: Application of the Von-Karman work equation in rolling processes.

- Extrusion: Analysis of the Extrusion Process: Examination of extrusion processes and pressure calculations.

- Drawing: Drawing Load: Methods for calculating drawing loads in metal cutting.

Theory of Metal Cutting Notes Pdf from VSSUT

The Theory of Metal Cutting (TMC) notes from VSSUT offer a comprehensive resource for understanding metal cutting processes. These notes cover fundamental concepts, practical applications, and detailed analyses essential for mechanical engineering students.

Always Choose Smartzworld to Download TMC Notes PDF

Smartzworld is a reliable platform for accessing high-quality educational materials. By choosing Smartzworld, you ensure that you are downloading accurate and well-organized notes that will support your studies effectively.

Benefits of FREE TMC Handwritten Notes PDF

Downloading free handwritten notes has several advantages:

- Comprehensive Coverage: The notes cover all critical topics required for understanding metal cutting processes.

- Clarity and Accessibility: Handwritten notes are often easier to read and comprehend compared to printed materials.

- Cost Savings: Free notes provide high-quality educational resources without any cost.

FAQs

Q1. Where can I download the Theory of Metal Cutting Notes Pdf?

You can download the notes from the provided links for each module or the complete set from Smartzworld.

Q2. How to download the TMC Notes Pdf?

Visit the provided links to access and download the TMC notes Pdf. Ensure a stable internet connection for a smooth download.

Q3. How many modules are covered in TMC Notes Pdf?

The TMC notes Pdf covers four main modules, each addressing different aspects of metal cutting.

Q4. Topics Covered in TMC Notes Pdf?

The notes cover a range of topics including stress analysis, plasticity theory, deformation processes, and process analysis in metal cutting.

Q5. Where can I get the complete TMC Handwritten Notes Pdf FREE Download?

The complete set of handwritten notes can be downloaded from the provided links or from Smartzworld.

Q6. How to download TMC Handwritten Notes Pdf?

Use the download links provided to access the handwritten notes Pdf. Follow the instructions on the website for a successful download.

Q7. How to Download FREE TMC Notes PDF?

Visit Smartzworld or use the provided links to download the free TMC notes Pdf.

For high-quality and detailed notes on Theory of Metal Cutting, always choose Smartzworld. These notes will be a valuable asset in your academic journey, helping you excel in your studies and understanding of metal cutting processes.

TEXT BOOK(S):

3. Mechanical Metallurgy: By- Dieter, Mc Graw Hill Book Co.

4. Plasticity- Chakraborty- McGraw Hill.

REFERENCE(S):

4. Engineering Plasticity: BY- Johson & Mellor, Van Nostrand.

5. Metal working –Avitzur, Mc Graw Hill

6. Industrial Metal working- G.W. Rowe

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 13

No votes so far! Be the first to rate this post.